Ultrasonic Anti-Fouling Technology

-The Problem-

Bio Fouling and consumption

With an estimated 62,000 vessels in the world trading fleet and an estimated 350 million metric tons of marine fuels being consumed per anum, the numbers are astounding. Assuming even a conservative 10% increase in fuel consumption being caused by biofouling we can estimate the environmental impacts of additional consumption to be in excess of 31.8 million metric ton of marine fuels and emissions.

If the environmental impact is not enough to ponder ultrasonic as a solution, the math on fuel cost vs additional consumption alone should be. At the conservative estimate of 31.8 million metric tons of additional marine fuels at a cost of ~$1,100 USD per metric ton the biofouling induced costs are ~$35 Billion USD per anum when considering ONLY the fuel consumption.

Beyond the above mentioned environmental and financial costs, there is also increased maintenance, additional docking, cleaning, trip duration (caused by reduced performance), cooling efficiency loss and more.

-The Problem-

Raw Water & Cooling

Raw water cooling systems are utilized in virtually all of the 62,000 vessels in operation around the world. Through the use of raw seawater for cooling or heat exchangers.

This represents yet another alarming issue when biofouling is left unchecked and cooling efficiencies and flow rates are lost, increasing the need for cleaning maintenance or repairing equipment damaged by blockages, overheating and other biofouling related issues.

-The existing Solutions-

Antifoulant paints

HULLS / STRUCTURES / RUNNING GEAR

Protection of marine surfaces has traditionally always been performed solely with specialist ablative paints that contained biocides, toxins and heavy metals. Over time legislation continues to restrict the use of toxic additives as more and more countries look towards the real and concerning environmental impacts of these chemicals in our oceans.

As the industry adjusts to the tightening constraints on anti-foulant paints and their toxic ingredients, it is looking for a more environmentally friendly solution to control bio fouling. The application of ultrasonic energy to this end is a natural progression when the factors are considered and as ultra-sonication utilizes acoustic energy it naturally requires zero chemicals to provide protection.

New less harmful Antifoulant paints can far out perform their previous more toxic versions when used in conjunction with ultrasonic anti-fouling.

Impressed Current Antifouling (ICAF)

RAW WATER / PIPES / BOX COOLERs

When it comes to cooling systems, the process is typically the use of impressed current antifouling. Essentially an isolated DC current is induced into the water intake or box cooler sea chest between two sacrificial electrodes with the intention of depleting the heavy metal from those two electrodes directly into the water and provide a steady flow of the toxic element, typically copper. Naturally this solution is not inherently environmentally friendly and requires ongoing expensive maintenance to replace, maintain and monitor the systems. Along with the serious risk of induced electrolysis if stray currents or similar occur.

-The Ultrasonic Solution-

Ultrasound has been used in industry for decades; sterilization in medical sector, welding for plastics, cleaning of parts in industry, algal control solution in food production and many many more.

Through the use of targeted ultrasonic transducers it is possible to provide acoustic sonication to generate non-inertial cavitation bubbles at a low amplitude providing a scrubbing / cleaning effect and a sterilization / disruption effect to the growth of micro-organisms and algae within the immediate vicinity of the structures being protected.

This technological adaption and advancement allows us to bring bio fouling prevention to the marine sector without any introduction of toxin, heavy metals, biocides or similar. Essentially utilizing acoustic energy to achieve the results. Read on below to learn more.

Ultrasonic Pressure is Key

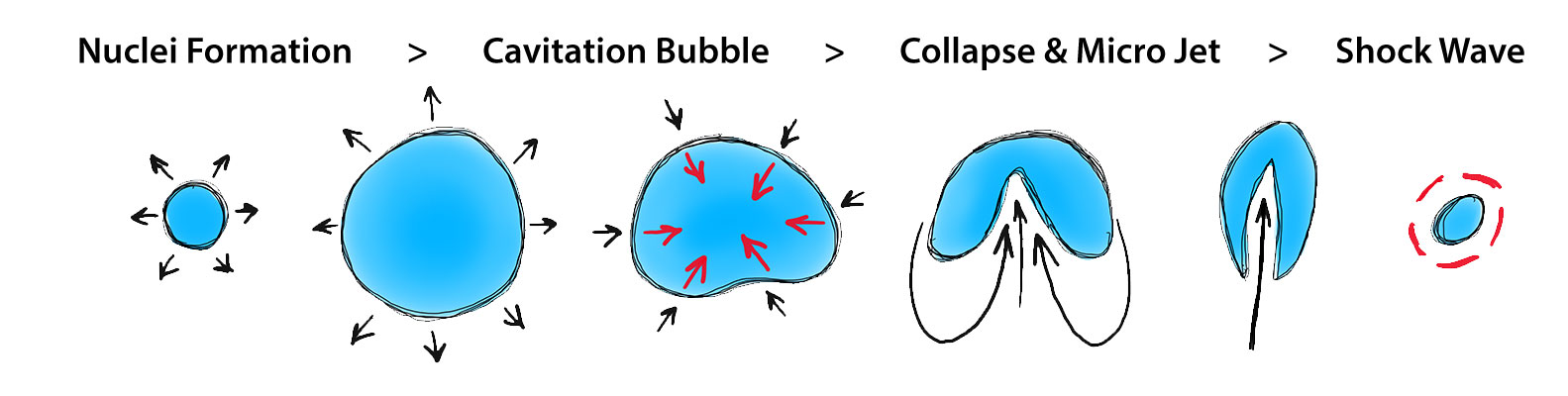

Ultrasonic energy is emitted into the structure / surface of the material at carefully targeted frequencies and power levels. This ultrasonic acoustic energy produces a series of pressure variations, high (compression) & low (rarefaction), within the liquid that in turn form microscopic non-inertial cavitation "bubbles" on or near to the surface or impurities within the fluid where they can nucleate. The process of generating and destroying these "bubbles", at various targeted sizes (frequencies), produces both an agitation of the surface area for the cleaning effect and damage to the cell wall of microscopic algae/bacteria where the non-inertial cavitation occurs on or near to the impurities.

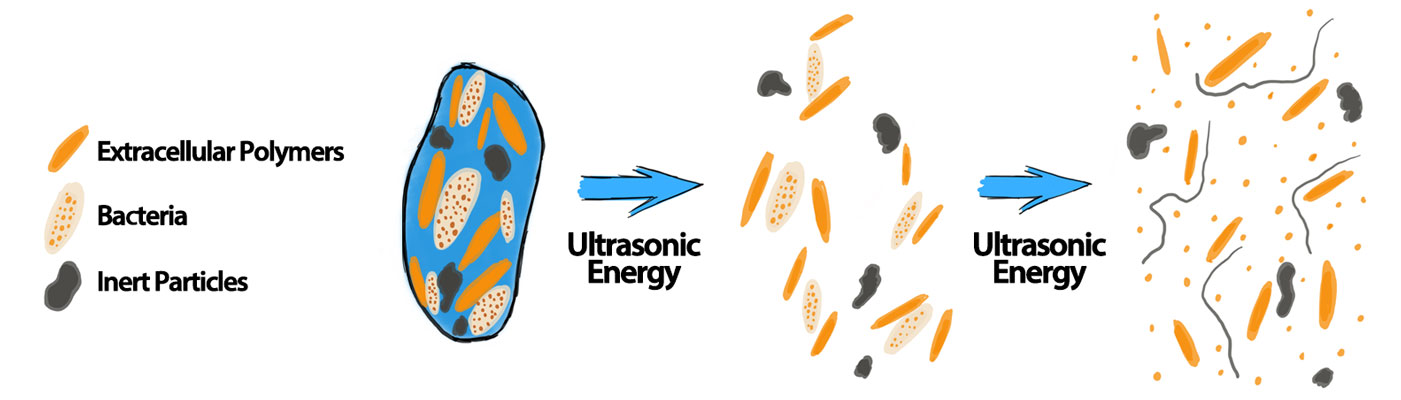

Ultrasonic Acoustic Disintegration of Algae & Bacteria

The diagram below shows the effects of ultrasonic acoustic energy on algae and bacteria. The ultrasonic cavitation causes disintegration of the cell wall of algae and bacteria reducing the same to inert particles and preventing continued colonization or growth.

Frequently Asked Tech Questions

Will ENVSonic Ultrasonic antifouling cause damage or degradation?

No. Our Ultrasonic systems are not going to cause any damage, pitting or degradation to surfaces or coatings.

ENVSonic uses very specific output amplitudes and frequencies to generate non-inertial cavitation bubbles for cleaning and bio-fouling growth prevention without causing any damage.

This is not to be confused with inertial cavitation or hydrodynamic cavitation that is induced on surfaces and known in the industry as a damaging, concerning maintenance factor in props, impellers and similar.

Does ENVSonic work on all surfaces?

ENVSonic works to protect all surfaces with the exception of wood.

Our technology utilises the material’s ability to carry and transmit the ultrasonic energy through the substrate and to the surface. Wood has a high attenuation property that prevents this from occurring effectively.

ENVSonic is excellent for anti-fouling protection of steel, stainless steel, aluminium, titanium, FRP/GRP, kevlar, carbon fibre, and PVC/ABS (rigid plastic).

Where silicone based coatings are used transducer spacing will need to be adjusted to compensate due to silicone based absorption of ultrasonic energy reducing effectiveness.

Protect Environment and Save $$

Ultrasonic anti-fouling is the most environmentally friendly bio fouling solution. Unlike impressed current systems or toxic paints, ultrasound produces no toxin / biocide or heavy metal oxides.

Protect your assets

Suitable for any submerged surface. Protection for everything hulls, thrusters, shafts, propellers, jet drives, rudders to box coolers, sea chests, seawater pipes, valves, intakes and more.

Solutions. End to End.

ENVSonic has a solution for all applications. And if we don’t, we will engineer it. As the OEM we control the solution, end to end.

Enquire about ENVSonic Ultrasonic Antifouling Systems

Enquire now to open a dialogue, obtain our literature and get protected. We are happy to discuss your requirements and answer any questions.