Seachests, Box Coolers & Pipeworks

Box Coolers, Sea Chests, Raw Seawater Pipes and Heat Exchangers are the most critical factors for cooling efficiency and essential for the consistent functionality of all vessels. Bio-fouling within the systems can severely reduce the systems cooling capacity and severely effected flow rates can cause damage or critical failure resulting in major repair or downtime.

Sea Chest & Box Coolers

Box coolers are used in many vessels throughout the industry. Box coolers are prone to bio-fouling, with constant seawater flow through the thin tubes there is a constant flow of nutrients. Without a suitable bio-fouling prevention system (MGPS) in place the box cooler and sea chest would quickly become fouled with algae, barnacles and other fouling.

Our MGPS can prevent bio-fouling on the surface of the box cooler by producing bursts of alternating high and low pressure ultrasonic acoustic energy. This energy generates microscopic bubbles that form and collapse in a process called non-inertial cavitation. The energy released by these bubbles create and environment where algae and microorganisms cannot continue to survive or adhere to the piping of the box cooler, maintaining the cooler and it’s efficiency.

Sea Strainer, Pipework & Heat Exchanger

In many vessels raw seawater is used for many functions, typically flowing through heat exchangers for cooling engines, hydraulics and more, fire fighting systems, etc. These systems typically flow the seawater into the vessel via a sea strainer, sometimes a filter, and go on to a manifold and through a network of pipes.

Much like with box coolers and sea chests, biofouling within the cooling pipes and heat exchangers is a major problem, any level of fouling within the sea strainer / manifold / pipes or heat exchangers can begin to cause efficiency and cooling loss with reduced flow rates. If growth reaches a critical point it can cause catastrophic issues within the connected devices.

ENVSonic MGPS can work to maintain the intake sea strainers through the strategic placement of our ultrasonic transducers. By producing bursts of microscopic ultrasonic non-inertial cavitation bubbles into the raw seawater within the pipe we can work towards cleaning away forming growth on the surfaces and preventing settlement.

ENVSonic. Simple Installation. Solid Results

Installation of ENVSonic Ultrasonic Anti-Fouling is a simple process that does not require docking or downtime. Transducers are installed inboard without the need for cutting, welding or modifications, using our supplied 2 part epoxy and the mounting footprints. The system can even be installed to work along side any other bio-fouling prevention system for added protection.

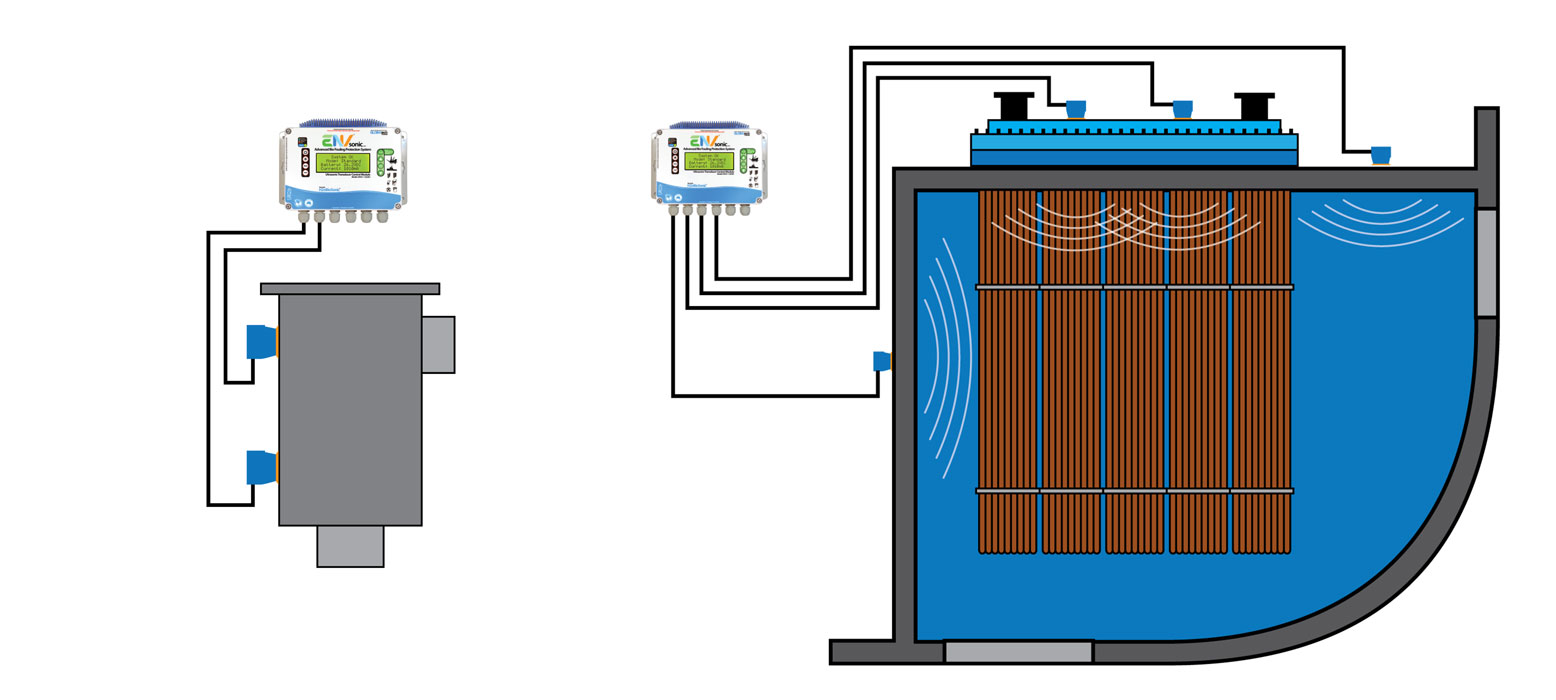

To the right is a basic representation of a Sea Strainer and Box Cooler / Sea Chest configuration. The number of transducers and locations is typically provided with a layout by our team, there may be more or less than shown here depending on the application.

Ultrasonic Anti-Fouling is quickly becoming a standard in the marine sector.

Enquire about ENVSonic Ultrasonic Antifouling Systems

Enquire now to open a dialogue, obtain our literature and get protected. We are happy to discuss your requirements and answer any questions.