Ultrasonic Anti-Fouling Studies

The effectiveness of ultrasonics for anti-fouling has been the subject of numerous studies. :

Ultrasonic Effects on Algae Cells: A study evaluated the effectiveness of power ultrasound in inactivating algae cells at a pilot scale. The results demonstrated that ultrasonic treatment could significantly reduce algae concentration in water. The study used two commercially available ultrasonic systems capable of scaling up to industrial levels, showing potential for effective large-scale algae control (MDPI).

Biofouling Control Using Ultrasonic and Ultraviolet Treatments: An investigation into non-chemical techniques, including ultrasonic and ultraviolet treatments, showed that these methods could effectively control biofouling by deactivating microorganisms and preventing the formation of colonies. This approach increases the induction period of low fouling rates and is a promising alternative to traditional chemical methods (OSTI).

A novel strategy for cyanobacterial bloom control by ultrasonic irradiation: This study evaluates the use of ultrasonic irradiation to control cyanobacterial blooms in a eutrophic lake. Ten Ultrasonic Irradiation System (USIS) units were installed in Lake Senba and monitored over two years. The combination of ultrasonication and water flushing significantly improved lake conditions by reducing chlorophyll-a, COD, and T-P levels. Laboratory experiments also showed that ultrasonic irradiation destroyed cyanobacteria by disrupting their gas vacuoles and promoting contact with lysing bacteria, leading to accelerated cell destruction (NCBI).

Ultrasonic Pressure is Key

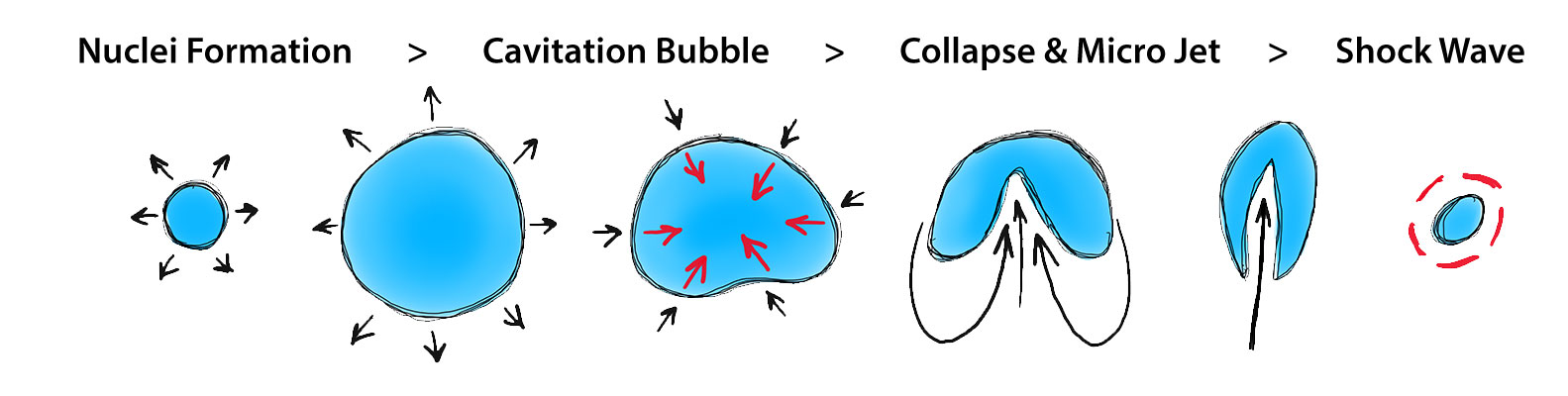

Ultrasonic energy is emitted into the structure / surface of the material at carefully targeted frequencies and power levels. This ultrasonic acoustic energy produces a series of pressure variations, high (compression) & low (rarefaction), within the liquid that in turn form microscopic non-inertial cavitation "bubbles" on or near to the surface or impurities within the fluid where they can nucleate. The process of generating and destroying these "bubbles", at various targeted sizes (frequencies), produces both an agitation of the surface area for the cleaning effect and damage to the cell wall of microscopic algae/bacteria where the non-inertial cavitation occurs on or near to the impurities.

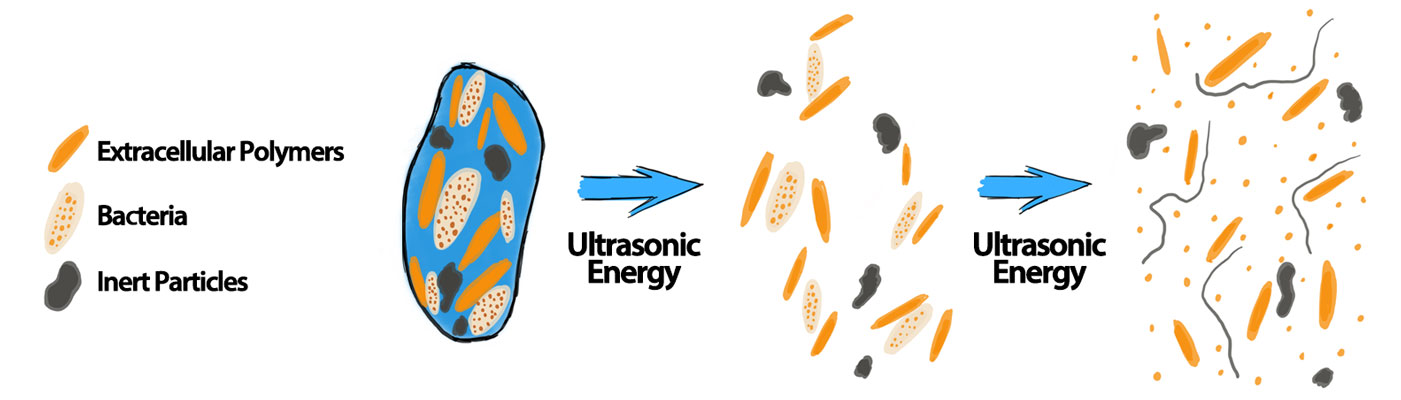

Ultrasonic Acoustic Disintegration of Algae & Bacteria

The diagram below shows the effects of ultrasonic acoustic energy on algae and bacteria. The ultrasonic cavitation causes disintegration of the cell wall of algae and bacteria reducing the same to inert particles and preventing continued colonization or growth.

Enquire about ENVSonic Ultrasonic Antifouling Systems

Enquire now to open a dialogue, obtain our literature and get protected. We are happy to discuss your requirements and answer any questions.