ENVSonic Ultrasonic ANTI-Fouling Technology

The Benefits

Efficiency and Performance - Fuel Savings

Ultrasonic antifouling creates an uninhabitable environment for larger organisms, preventing biofouling from the start. The microscopic water movement from non-inertial cavitation deters algae, barnacles, and other larvae from settling on surfaces. This keeps surfaces smooth, ensuring optimal flow rates, hydrodynamic efficiency, fuel consumption, and emissions.

Cooling Improvements - Reduced Maintenance

Applying ultrasonic antifouling to raw water systems, pipes, box coolers, sea strainers, and heat exchangers significantly reduces or eliminates biofouling. This maintains high cooling efficiency, optimal flow rates, and reduces maintenance needs, downtime, and related costs.

Reduced Chemical Loads

Ultrasonic sterilization drastically reduces or eliminates the need for biocidal dosing, exceeding industry standards for cfu/ml plate counts and algae levels in HVAC chiller towers. This makes chiller water recyclable, protects the environment from legionella, and reduces ongoing maintenance and costs.

How Ultrasonic Antifouling works?

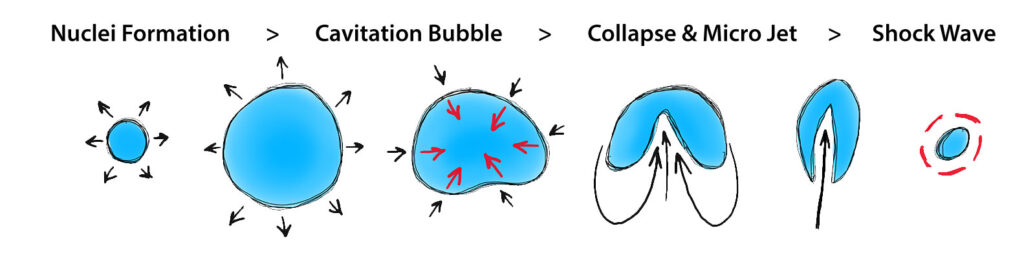

ENVSonic ultrasonic antifouling works by producing a series of carefully curated and targeted bursts of ultrasonic energy (acoustic sonication).

These bursts of energy are transmitted via our ultrasonic transducers, installed in strategic locations, into the structures to be protected.

The result is ultrasonic energy generating microscopic bubbles that provide the protection within the water column.

Key System Benefits & Features

Reduced Fuel Consumption

Reduced fuel consumption by up to 30% & reduce trip times with a clean hull, rudders and props.

Protect the Environment

No Toxins, No Biocides, No Heavy Metals and reduced consumption. Environmental protection at it’s best.

Simple Installation

No docking necessary*, No expensive ongoing maintenance parts, No through hull parts or welding required.

Reduced Operating Costs

Reduced downtime, extended docking intervals, improved reliability, reduced fuel consumption, improved trip times.

Simple Vessel Integration

Vessel monitoring and integration with SCADA and others for isolation control and error detection.

Universal Power Options

Native 12 / 24VDC & uninteruptable dual power options. 100 – 240VAC No problems.

Transducer Calibration

Automatic individual transducer calibration & advanced targeted algorithms for improved protection.

Individual Channel Control

Each Transducer monitored and tested with individual channel isolation and control. Detects issues and maintain protection, always.

Multiple Power Modes

3 built in power modes control the output level.

Low Power, Normal output and Boost. It’s up to your application requirements.

ECONOMY. STANDARD. BOOST.

Targeted system modes

Tell the system where it is installed for even better results. Modes; Hull/Chest, Box Cooler, Heat Exchanger, Running Gear, Pipe, Water Column.

System Certification

The only system in the world that carries FCC, CE & RCM certification for the entire system.

GOLD & Protected PCB

Gold plated, Lead Free, Conformally Coated.

ROHS compliant, marine grade PCB’s.

* Installations within ballast tanks require class approved cable penetrations where docking is usually necessary.

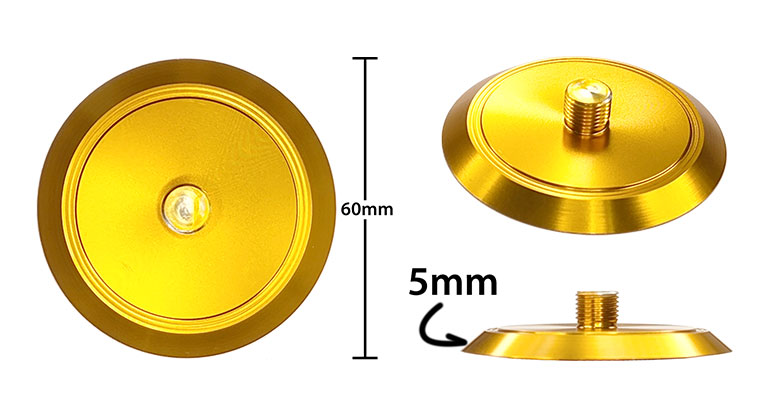

Transducer

Advanced Technology. Small Package.

ENVSonic Transducers are a sophisticated device consisting of proprietary assembly and material technologies designed to last. From our primary and secondary mass material, our specially treated PVC outer shell or even our own industrial silicone rubber tinned copper cable.

Each transducer is put through a rigorous analysis before being hermetically sealed with a special degassed potting process, completely encapsulating the transducer end to end. Providing an industry leading IP68 protection beyond 10m of depth! Every ENVSonic transducer produced is ready for anything from a dry box cooler install to being submerged inside a ballast tank, for life.

Footprint

Elegant Mounting Solution. Extreme Results.

ENVSonic Transducers are attached by our patented mounting footprint. This proprietary mounting footprint provides the simplest installation while adding the benefits of a water tight seal, electrical isolation and improved ultrasonic transference over the silicone grease or isolated transducer face methods. By ensuring the transducer is monolithic with the structure using our footprint we are;

- Up to 30% additional ultrasonic energy transference

- Reduced attenuation.

- Eliminating the risk of breakdown of silicone grease

- Eliminating the chance of induced loosening due to course threaded plastic fittings

- Cutting maintenance, service and inspection requirements.

Control Module

Advanced Ultrasonic Control Module. Self Aware.

The ENVSonic control module is the brains of the solution and generates the ultrasonic output to drive and monitor both itself and the transducers. Through constant measuring of a plethora of temperature, voltage, input and current sensors the control module runs an advanced proprietary algorithm to generate the output to the transducers.

ENVSonic systems include individual transducer monitoring and calibration functions. Monitoring to determine the health and integrity of each transducer and calibration to ensure the built in algorithm knows exactly how the transducer has profiled it’s new environment and carefully construct the best protection. Transducer monitoring can even detect when a transducer is not bonded properly to your vessel and shut down the channel so it can be fixed without damage.

- Only solution to carry FCC, CE, RCM compliance tested certification

- 2 Year Warranty. Peace of mind

- 12 or 24VDC natively with Dual un-interrupted AC / DC Options

- Full Character display. All information, available all the time. Along with a RGB quick view LED

- 3 Output Power Modes at the touch of a button for convenience in power conscious environments; ECONOMY. STANDARD. BOOST.

- 2 and 4 Channel Systems Available. Use of multiple systems for larger installations, no problems.

- Internal fused protection, with monitoring

- IP67 Polycarbonate Enclosure with anodized aluminium heatsink

- Vessel integration with isolation control and alert output

- Specific operating mode configuration from within system menu. Tell the device where it’s installed and it will tailor the output algorithm even further.

- Individual Channel control. Using only 3 of the 4 channels? No problem, just turn off the channel(s) not in use from the system menu

- Built in 4 and 8 hour sleep/isolation function

- Real-time data recording. Internally recording timers for life

Protect Environment and Save $$

Ultrasonic anti-fouling is the most environmentally friendly bio fouling solution. Unlike impressed current systems or toxic paints, ultrasound produces no toxin / biocide or heavy metal oxides.

Solutions. End to End.

ENVSonic has a solution for all applications. And can scale or customize any solution for any application. As the OEM we have complete control of our product, end to end. You are supported by the manufacturer.

Protect your assets

Suitable for any submerged surface. Protection for everything hulls, thrusters, shafts, propellers, jet drives, rudders to box coolers, sea chests, seawater pipes, valves, intakes and more.

The future of USAF / MGPS is now…

The latest release from Globa.tech Australia is the ENVSonic ENVS5-300, the solution to marine growth prevention via ultrasonic antifouling that the industry has longed for.

With this release we have merged the latest in technology, engineering, development and our proven track record as the USAF pioneers. This system is equipped to handle any industrial ultrasonic biofouling prevention needs, based on industry standards for cabinet mounting, remotely monitored and controlled, scalable to any size deployment and intensely powerful.

Contact us today to discuss your needs, we are happy to help.

Enquire about ENVSonic Ultrasonic Antifouling Systems

Enquire now to open a dialogue, obtain our literature and get protected. We are happy to discuss your requirements and answer any questions.